CULTURA SUISSE 2024

Wir sind an der Cultura Suisse in Bern vom 10.-12. April 2024. Besuchen Sie uns am Stand 1.228! Wir freuen uns darauf, Ihnen an der Cultura Suisse persönlich unser Produktportfolio und unsere Neuigkeiten vorzustellen.

mehr lesenSITEM 2024

Besuchen Sie uns auf der SITEM Paris 2024 (3.-4. April) am Stand B13! Wir freuen uns darauf, Ihnen an der SITEM persönlich unser Produktportfolio und unsere Neuigkeiten vorzustellen.

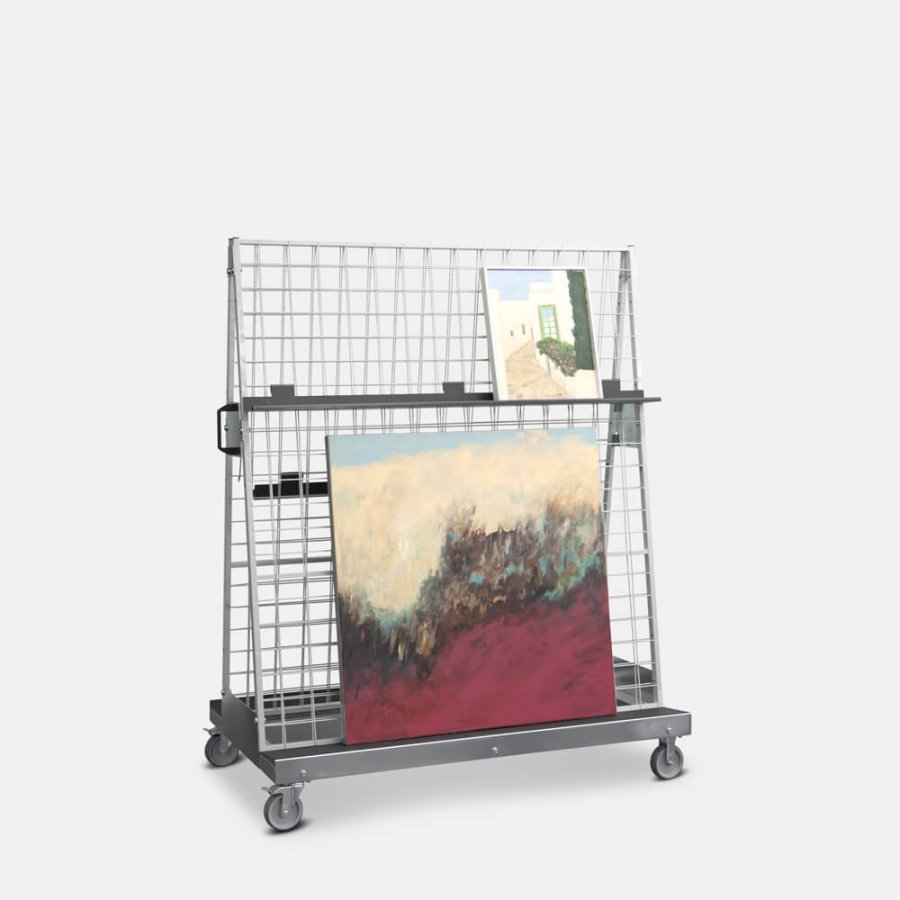

mehr lesenKunstaufbewahrung und Gemäldelagerung - Gemäldedepots für Museen, Galerien, Kunstsammlungen

Mit der Marke «ArtStore» hat sich die Firma Kern Studer AG auf die Herstellung und Installation von Bilderzuganlagen für Gemäldedepots und Schaudepots spezialisiert. Dabei zählen Museumsplaner, Regalbauer, Depot- und Museumseinrichter zu den wichtigsten Partnern von ArtStore. Seit 20 Jahren bieten wir massgeschneiderte Systemlösungen für Kunstaufbewahrung, Gemäldelagerung und Depotausstattungen. Unser auf Gemäldedepotanlagen spezialisiertes Team, macht sich bei jedem Depot ein genaues Bild Ihrer Bedürfnisse und erstellt Ihnen die optimale Lösung. Zu unseren zufriedenen Kunden dürfen wir Museen und Kunstinstitutionen in der Schweiz und in ganz Europa wie Belgien, Deutschland, Frankreich, Litauen, Österreich, Schweden sowie weiteren Ländern weltweit zählen.

Professionelle Gemäldelagerung: Kunstschätze in Reichweite und Sicherheit – für Kunstmuseen werden Gemäldezuganlagen und Kunstaufbewahrung, z.B. mit Fachboden- und Stangenregalen, immer wichtiger. Über achtzig Prozent der Sammlungsobjekte vieler Museen lagert in Depots oder Aussendepots. Die Lagerung, dieser Objekte von unschätzbarem Wert für zukünftige Generationen, mit Hilfe sicherer Aufbewahrungssysteme, sind daher unerlässlich für Museen. Dabei machen die wachsenden Kunstsammlungen sowie der begrenzte Ausstellungsraum eine Erweiterung oder Umdisponierung eines Lagers nötig. Museumsverantwortliche denken immer mehr darüber nach, wie die Depotbestände der Öffentlichkeit noch besser zugänglich gemacht werden können. Auch für viele Galerien sowie institutionelle und private Kunstsammler stellt sich die Frage, welches denn die optimale Lagerung ihrer Gemälde sei. Bei ihnen werden Schaudepots zunehmend beliebter, da diese platzsparende Aufbewahrung mit unkomplizierter Ausstellung kombinieren. Artotheken sind ein weiterer Anwendungsbereich für anschauliche Gemäldezuganlagen, die zeitgenössische Kunstwerke in den grossen Depots teilweise an die Öffentlichkeit ausleihen.

Dabei ist die Kenntnis der jeweiligen Sammlung für die Planung und Umsetzung eines solchen Depots zentral. Grossen Einfluss hat insbesondere die Quantität für eine passende Lagerlösung. Ergänzend müssen auch Grössenrelationen und Materialität der einzelnen Werke als wichtige Faktoren im Prozess der Planungsphase berücksichtigt werden. Für eine erfolgreiche Realisierung von Kunstlagerprojekten sind die Planer, Hersteller und Monteure der jeweiligen Lagersysteme von zentraler Bedeutung.

Wir sind echte Profis in Sachen Gemäldezuganlagen, egal ob es sich um deckenlaufende Systeme, bodenlaufende Systeme oder Kompaktsysteme handelt. Unsere Experten begleiten Sie von der Planung bis zur Ausführung Ihrer Anlage und informieren Sie regelmässig über den Fortschritt des Projekts. Wir sind Ihr innovativer Partner, wenn es um Gemäldedepotanlagen geht. Unsere Mitarbeiter und Partner freuen sich auf ein interessantes Planungsgespräch.

Kontaktieren Sie uns jederzeit - wir freuen uns auf Sie!

Unsere Partner

«Kunden schätzen Zuverlässigkeit.»

Wir als Produzent sind angewiesen auf eine sehr gute Zusammenarbeit mit unseren Partnern und Kunden, die wir gerne auf der ganzen Welt beliefern.